Conveying Solutions

Conveyors are machines and equipment which carry ingredients, products, containers, packs or packaging components from one place to another.

There are a large number of different types of conveyor, designed to convey different types of product or to perform particular tasks. They can be divided into four main groups:

- Conveyors for bulk products e.g. powders or free flowing solids

- Conveyors for both bulk products and small unit loads

- Conveyors for small unit loads e.g. bottles or cartons

- Conveyors for large unit loads e.g. pallets or kegs

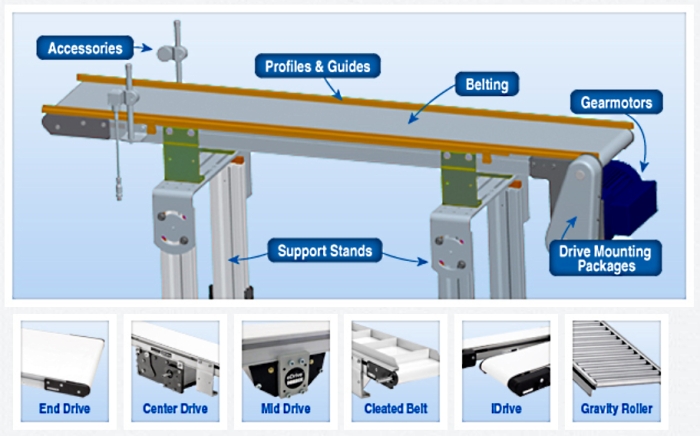

In their simplest form conveyors are mechanical assemblies which can be demountable and easy to move. In their most sophisticated form conveyors can be complex machines with drives, controls and sensors. In this form they undertake complex tasks or those needing highly accurate sorting, ordering or distribution of the items or products being conveyed.

Common forms of belt and slat band conveyors are used for all types of semi-automated or automated processing and packaging functions. They facilitate different requirements during production, and enable different products and packaging functions to be handled.

Some machines, such as large bakery ovens, include conveyors as part of the process, while high speed wrapping machines require in-feed and out-feed conveyors to be built in to operate at the speeds required.

Different consistencies of products, (soft, delicate, sticky, hot, chilled, frozen), require different handling techniques and so different designs of conveyor.

The ability to clean conveyors is an important requirement particularly in food or pharmaceutical plants where rigorous clean-in-place and wash-in-place regimes exist. These conveyors are often made of wire mesh, plastic mesh or stainless-steel and some can be dismantled or moved for ease of cleaning.

Packaging containers and components also need to be sorted or orientated, combined, indexed or unscrambled prior to being presented to the packaging machine, or to bring products packed on different lines together and specific types of conveyor have been designed to achieve all of these functions.