Manual Work stations

True manual assembly systems are typically individual workbenches for each stage in the assembly process. The product gets passed manually from station to station singularly or in batches. However, there are many variations to manual assembly. For example, you could also use a singular assembly line with a manual transfer conveyor. In this case, workers stand at a specific station along the line and manually push the product down the line as its being assembled. This is usually done in lower volumes rather than production runs.

We built the manual work stations by following the Ergonomics rules to make sure a fatigue less work zone.

We built the manual work stations by following the Ergonomics rules to make sure a fatigue less work zone.

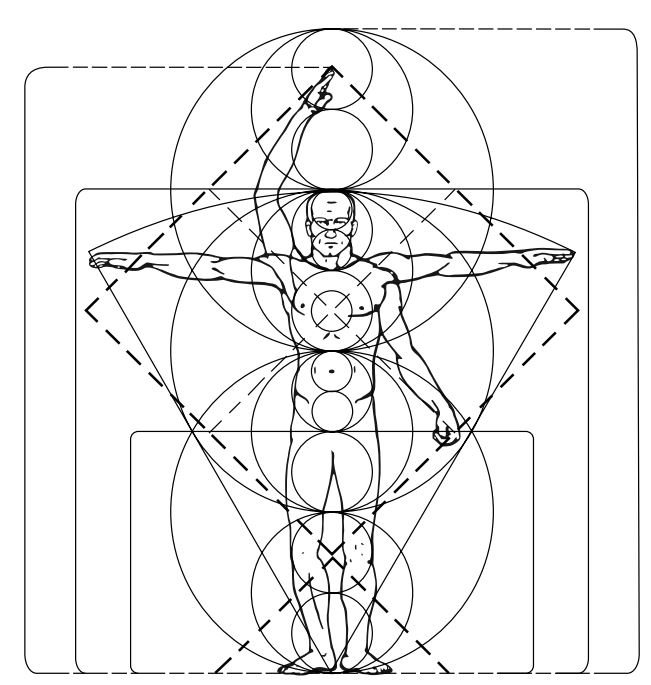

What is Ergonomics?

An ergonomics workstation facilitates work and maintains good health. Its aim to increase to motivation and satisfaction, higher performance, efficiency and processing quality, as well as fewer absences due to illness.

What is the benefit from ergonomics?

Ergonomics will provide you with valuable benefits I the form of higher productivity, increased efficiency, and a decisive edge over the competition –thus ensuring lasting success for your organisation.

The eight rules of ergonomics for work stations:

- Body height and working height

- Working area.

- Reach Zone.

- Parts Presentation.

- Range of vision.

- Lighting.

- Adjustment of working equipment.

- Planning and design tools.